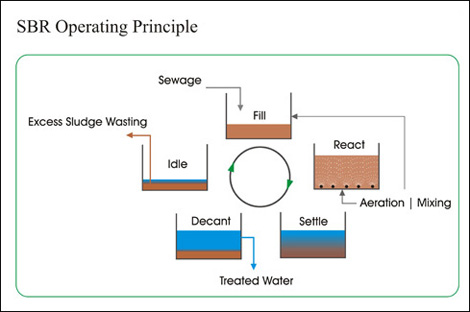

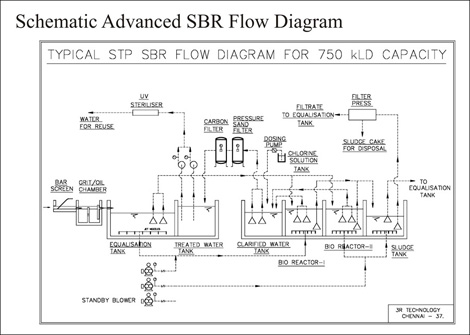

Sequential Batch Reactor (SBR) Technology

3R Technology introduces Advanced SBR Technology for Sewage Treatment, the technology was originally developed during 1995 for treating difficult industrial effluents. Automation along with extended aeration offers low sludge generation, consistent high quality effluent and free from many operational problems of conventional activated sludge process.

3R Technology offers 5 kLD to 2 MLD plants.

Package systems - 2.5 kLD to 250 kLD plants.

Benefits of Advanced SBR

SBR Applications

Downloads

Brochure:

SBR BrochureCase Study:

Case Study 220 Apartment-150 kldProject List:

List of Projects - 3R TECHWater Crisis Management:

Managing Water Crisis in Apartment CommunitiesFlexible Investment Plan:

Flexible Investment SchemeTest Results:

Water Test Results - SBR STP